Product Design, Modeling and Structural Analysis (FEA)

Structural Analysis (FEA)

Product Design

Design Automation

3D Modeling and Drafting

Detail Designing

Engineering Analysis

Tooling

Design Support

Design for manufacturing (DFM) concepts. Ease of assembly using Design for Assembly (DFA) concepts. Function and strength of the components. If your basic design is already complete, use our team for detailed design (assemblies and components).

Includes parametric solid modeling and drafting. Automated blueprint generation, knowledge based engineering, automated computer aided machining.

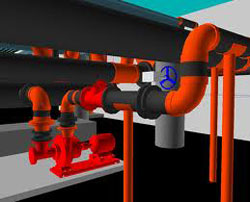

Includes solid and surface modeling, parametric feature based modeling, assembly modeling, detailed engineering, piping and routing, design automation, legacy data conversion.

Generation of drawings for parts and assembly. Manufacturing details and quality standards. Exploded views, dimensioning and tolerancing. Bill of Materials creation. Generation production drawings & assembly layout drawings per ISO, ASME, ANSI, and client specific standards.

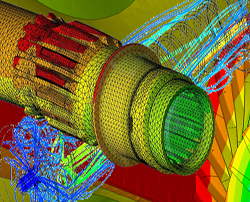

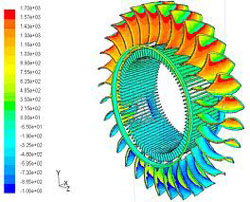

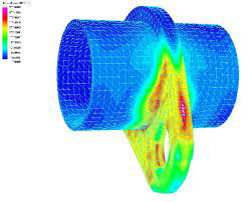

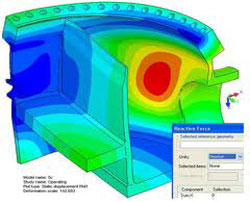

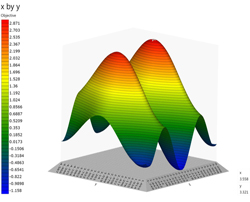

Includes finite element Meshing/Modeling (FEM), finite element analysis (FEA) under Static, Dynamic, Linear, and Non-linear conditions covering several aspects like Stress, Thermal, Fatigue and Durability Analysis, computational fluid dynamics (CFD), multi body dynamics (MBD). Kinematic and dynamic analysis of machinery and simulation. Fluid flow and combustion simulation.

Design of Jigs and Fixtures, precision injection molding, press tools, Patterns and dies using the latest concepts and technologies. We have expertise in single cavity, multi cavity and family Molds and have extensively worked with many varieties of plastics. We have the experience in the Welding, Inspection or checking BIW, Machining fixtures design and detailed drawing creation. Our tool design engineers are experienced in working with software like Unigraphics, Ideas, Pro E, Catia, AutoCAD, Mold flow, Delcam, etc., and are supported by a highly experienced team of tool manufacturing engineers ensuring high quality tools are designed.

Advantage Engineering has successfully executed many value engineering projects for customers and thereby measurable impact in Cost Optimization, Weight Reduction, Topology Optimization, Parts Optimization.